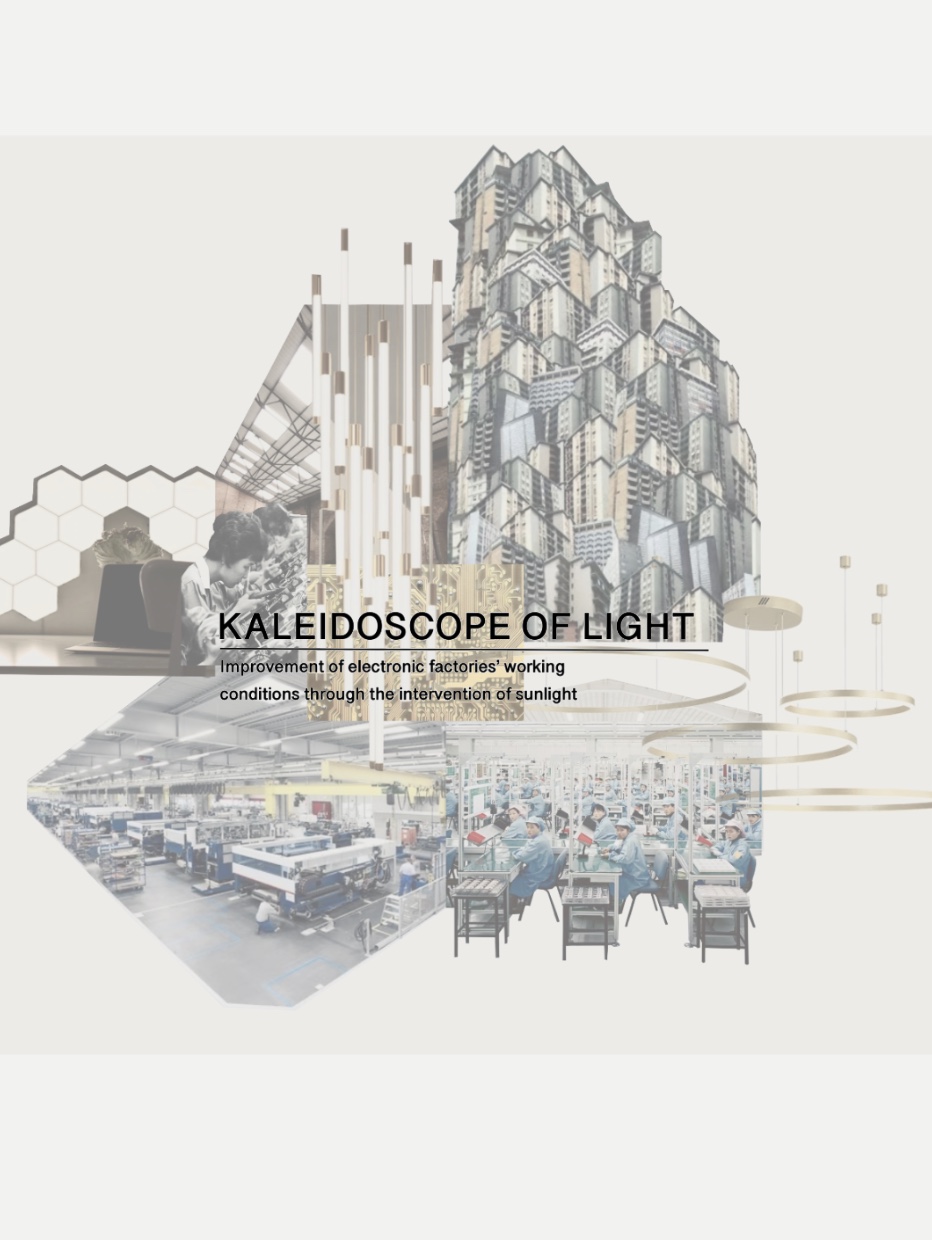

Kaleidoscope Of Light -- Improvement of electronic factories' working condition thorough the intervention of sunlight

Category

Daylight in buildings - Region 4: Asia and Oceania

Students

Xinting Ma

Chunman Li

Teacher

Shimeng Hao

School

Meiji University

Country

Japan

Download

Download ↓

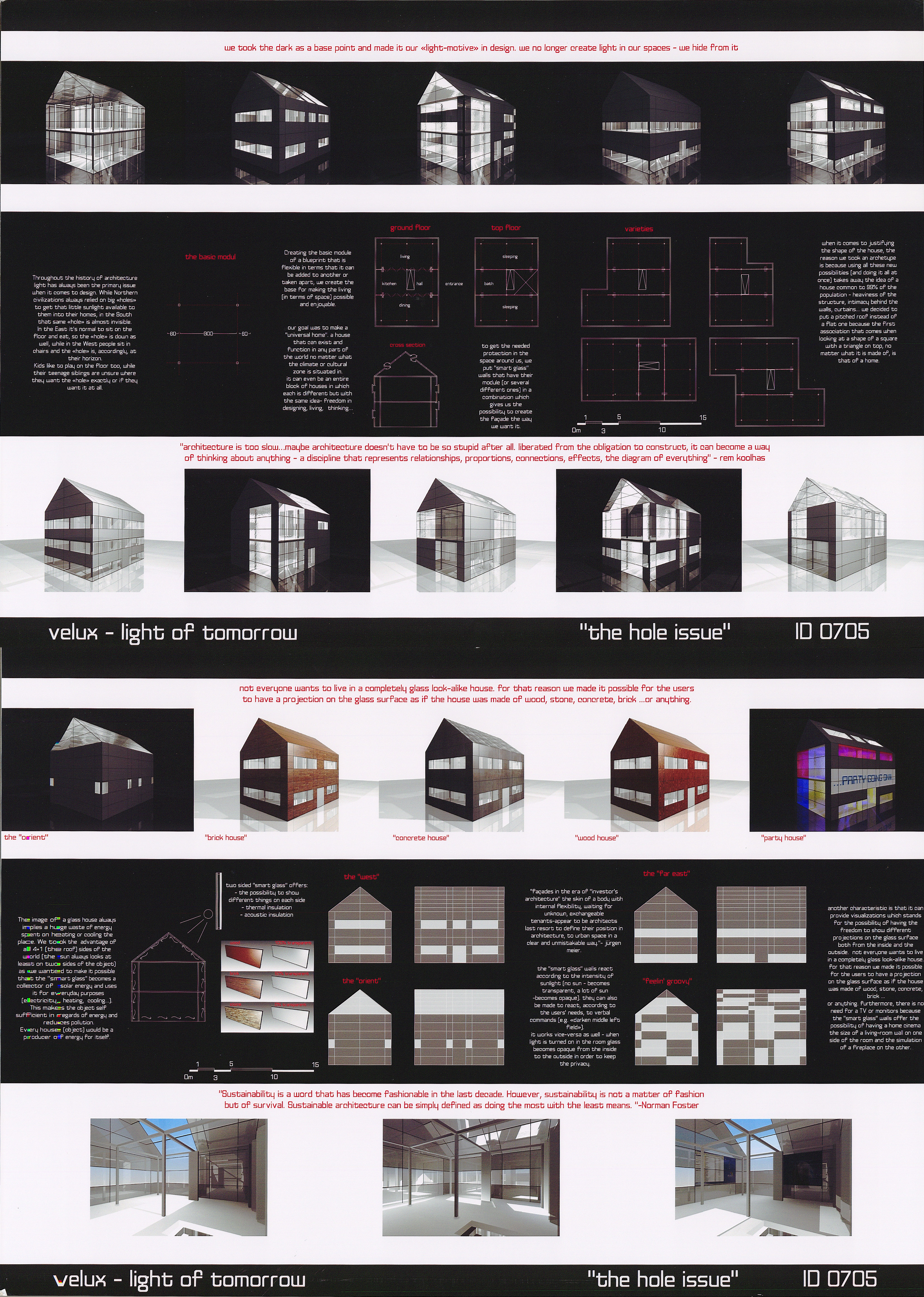

Some of the most famous and most used electronic equipment such as phones and laptops are assembled in electronics manufacturing factories in China. However, these factories are notorious for their poor working condition, excessive working period without overtime payment and the infamous incidents of factory workers who committed suicides and so on. Yet, shorter product cycles for electronic products in general and growing demand for new generations of technologies put increasing pressure on the industry and its complex supply chain to deliver new devices faster and at a lower cost. The result to which leads to even more inadequate working condition for the employees.

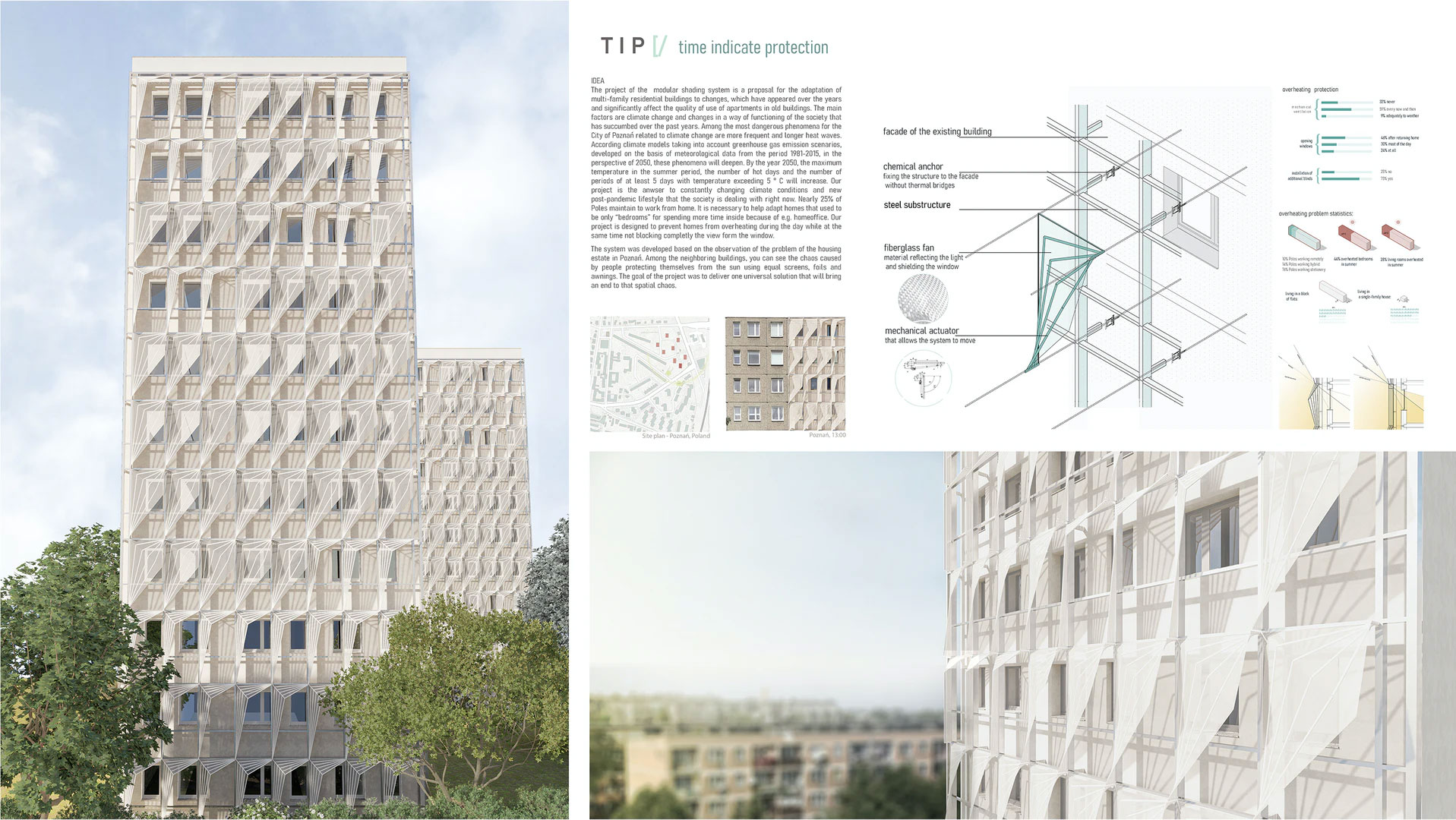

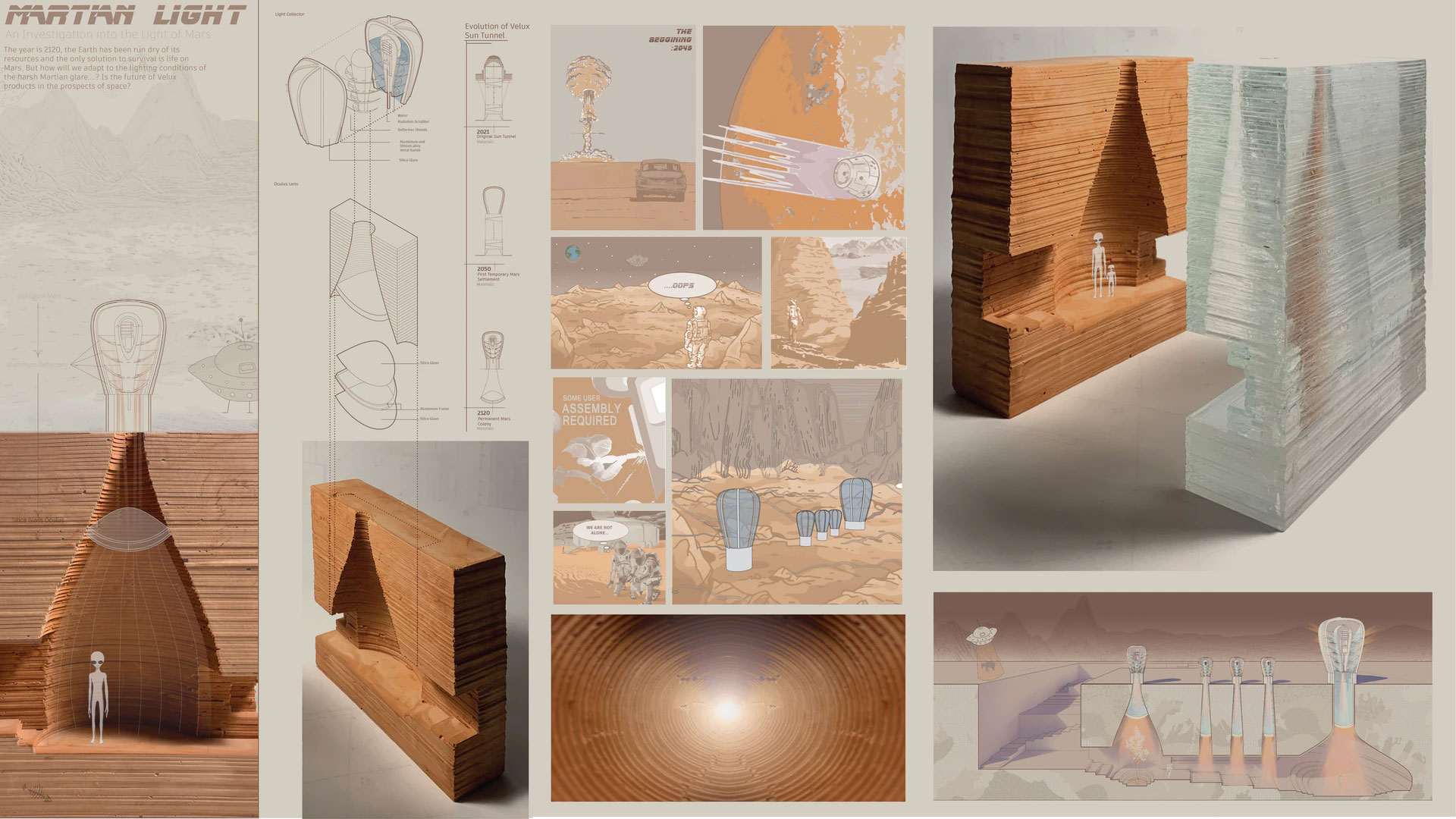

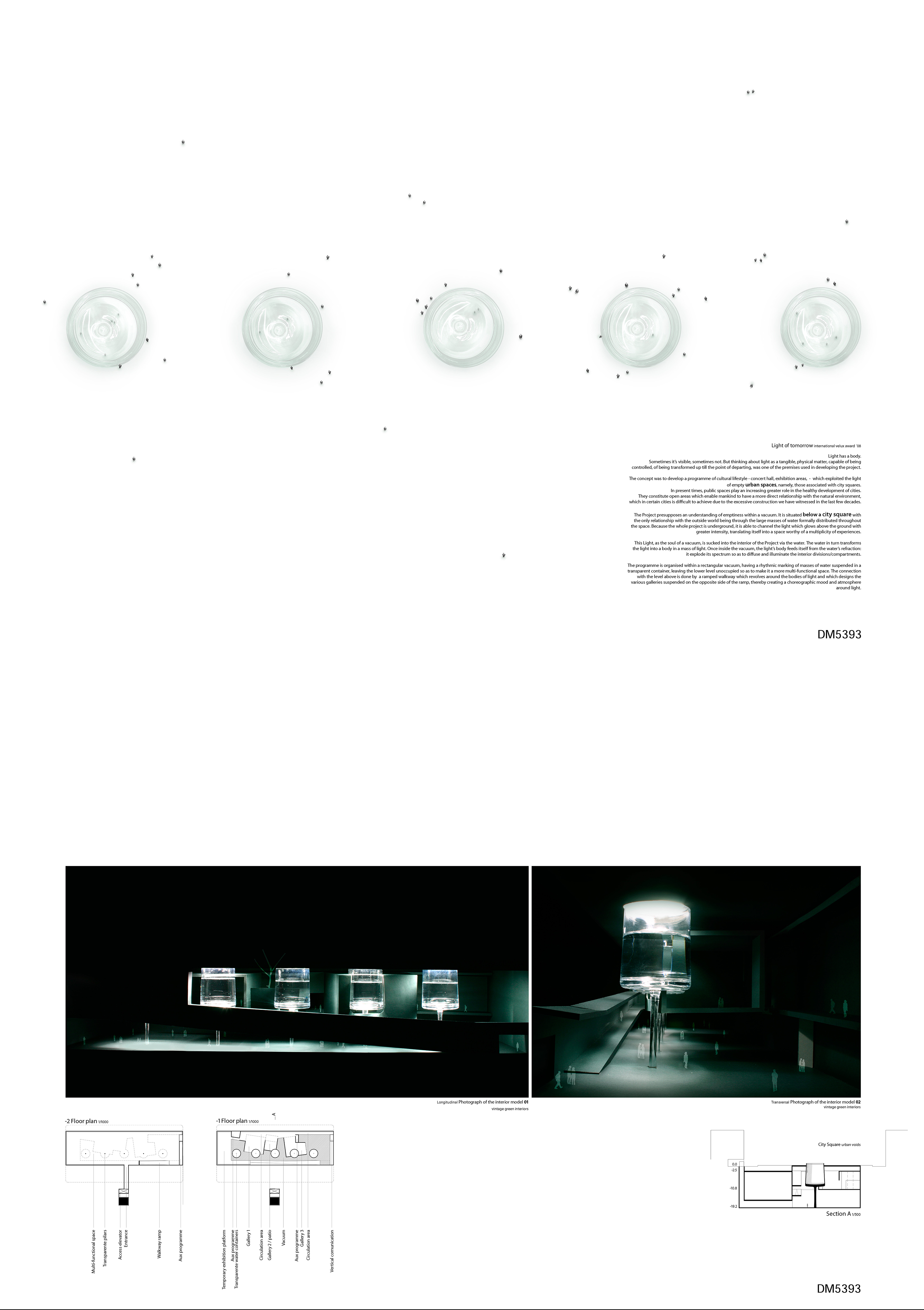

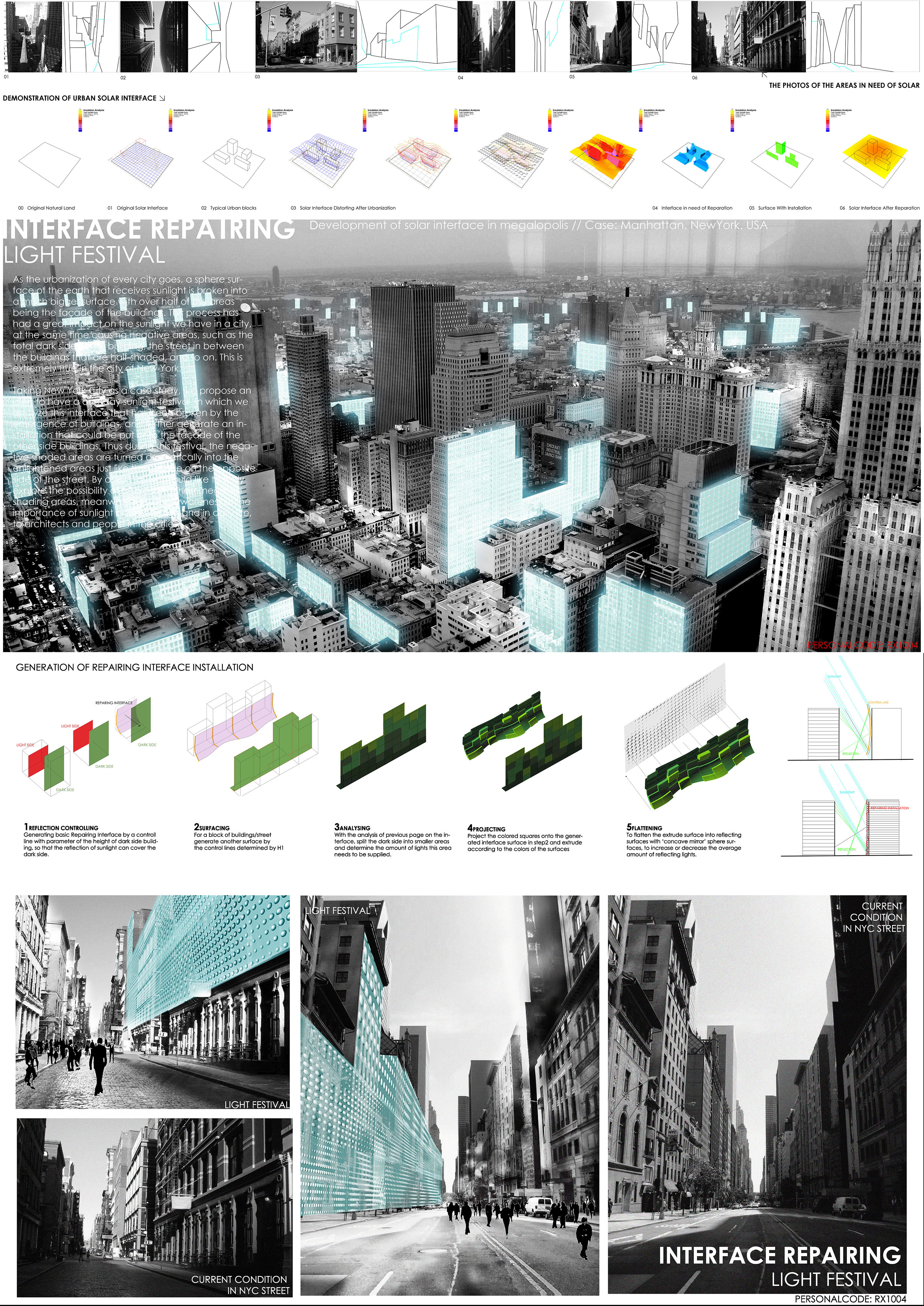

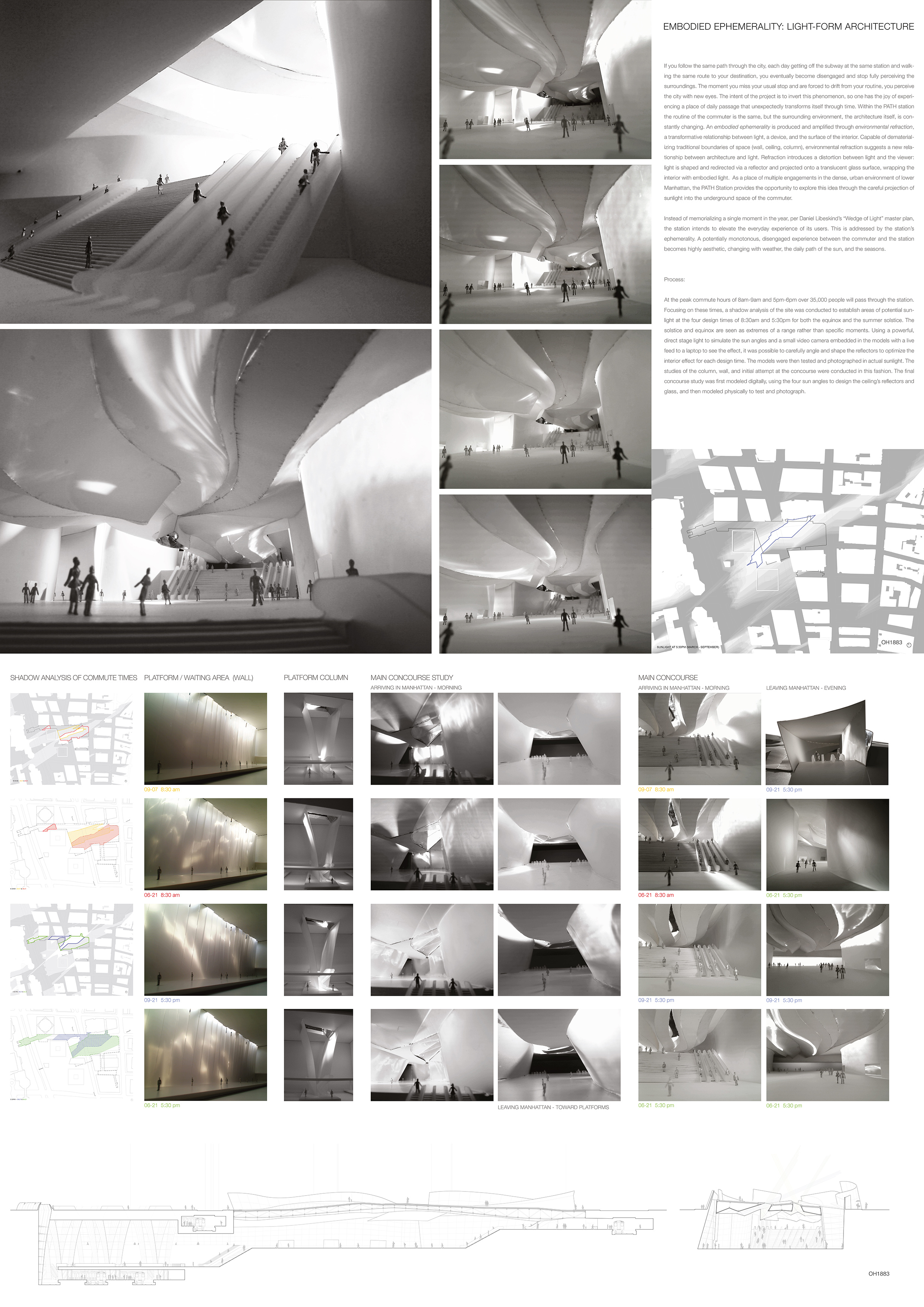

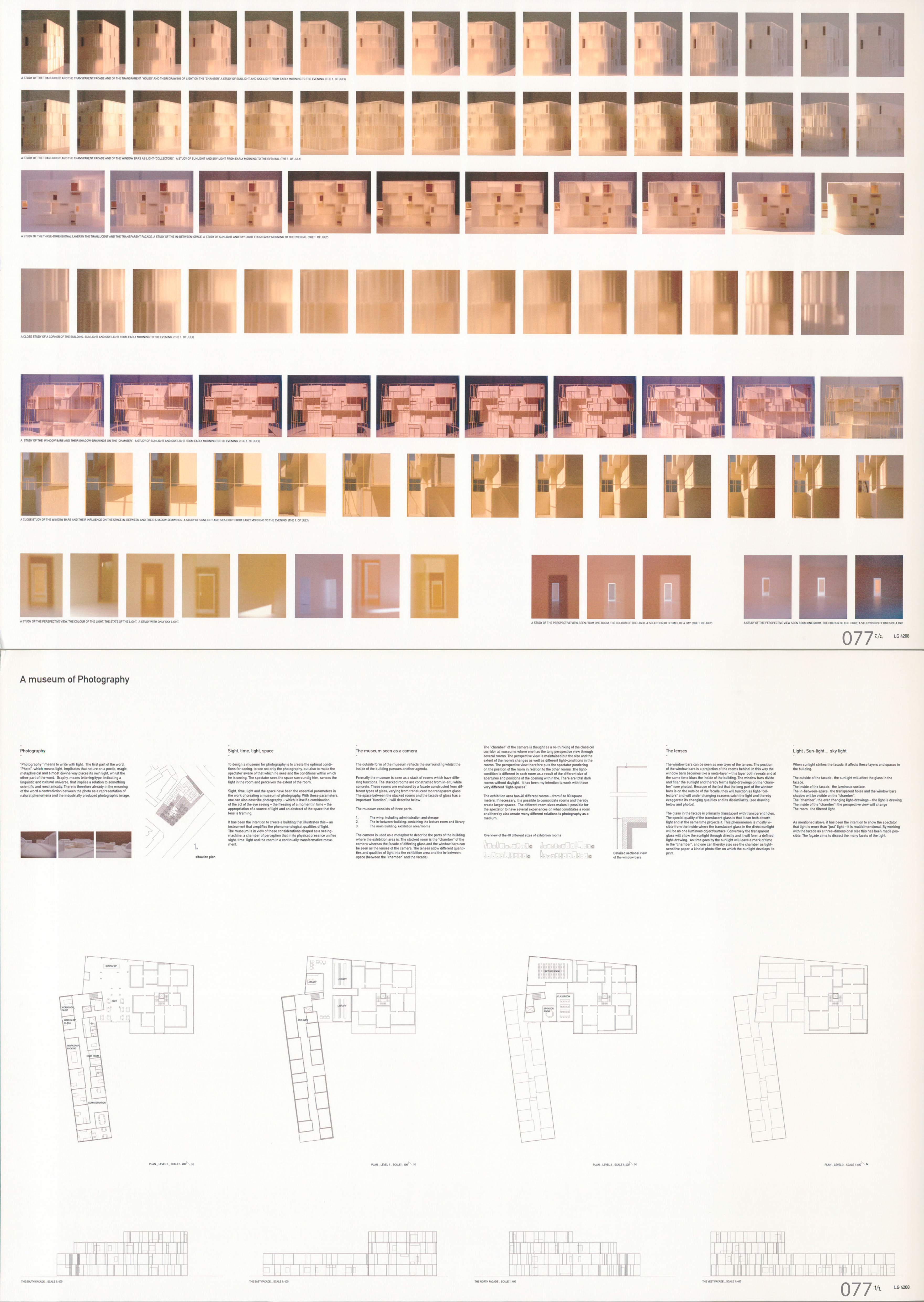

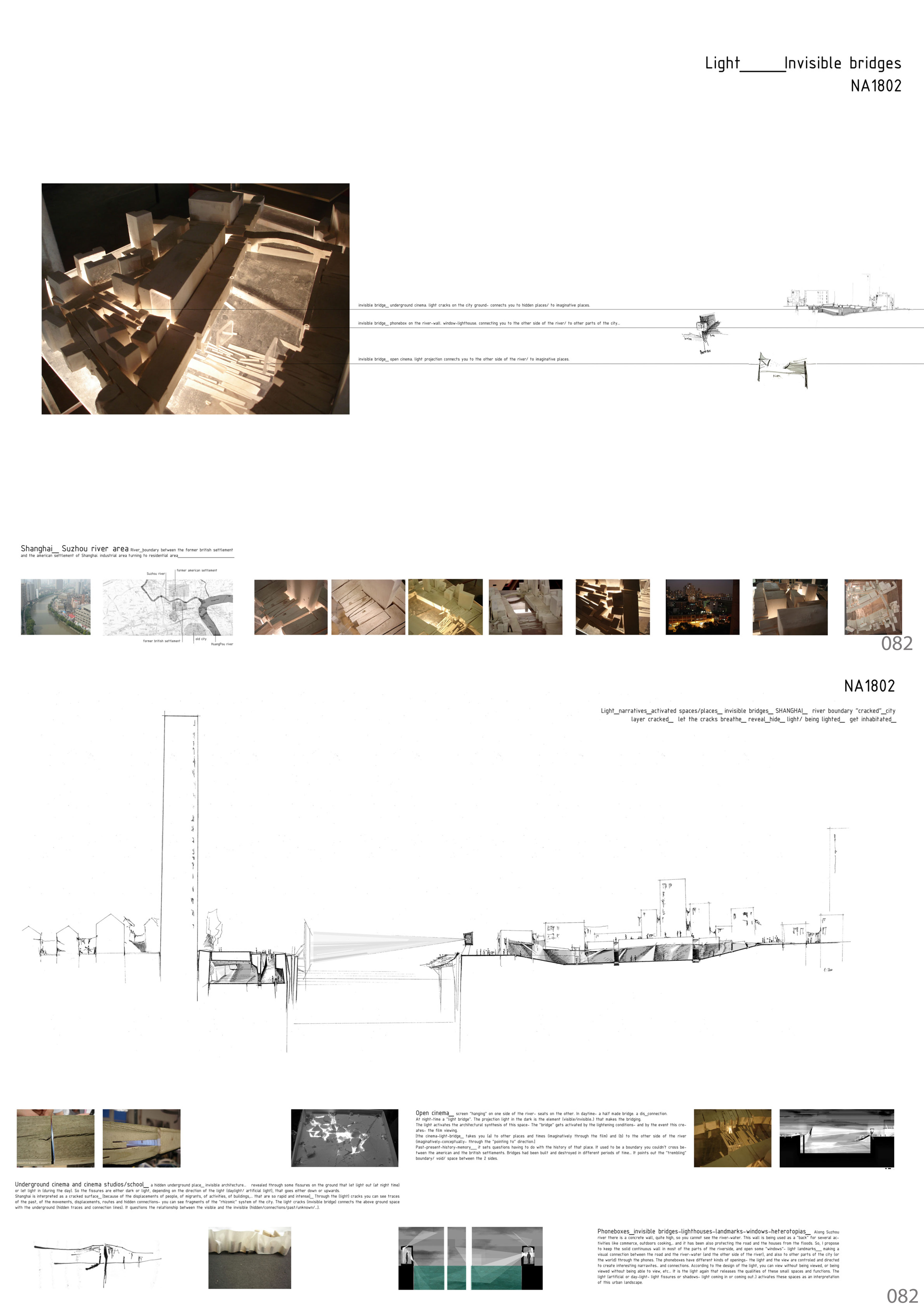

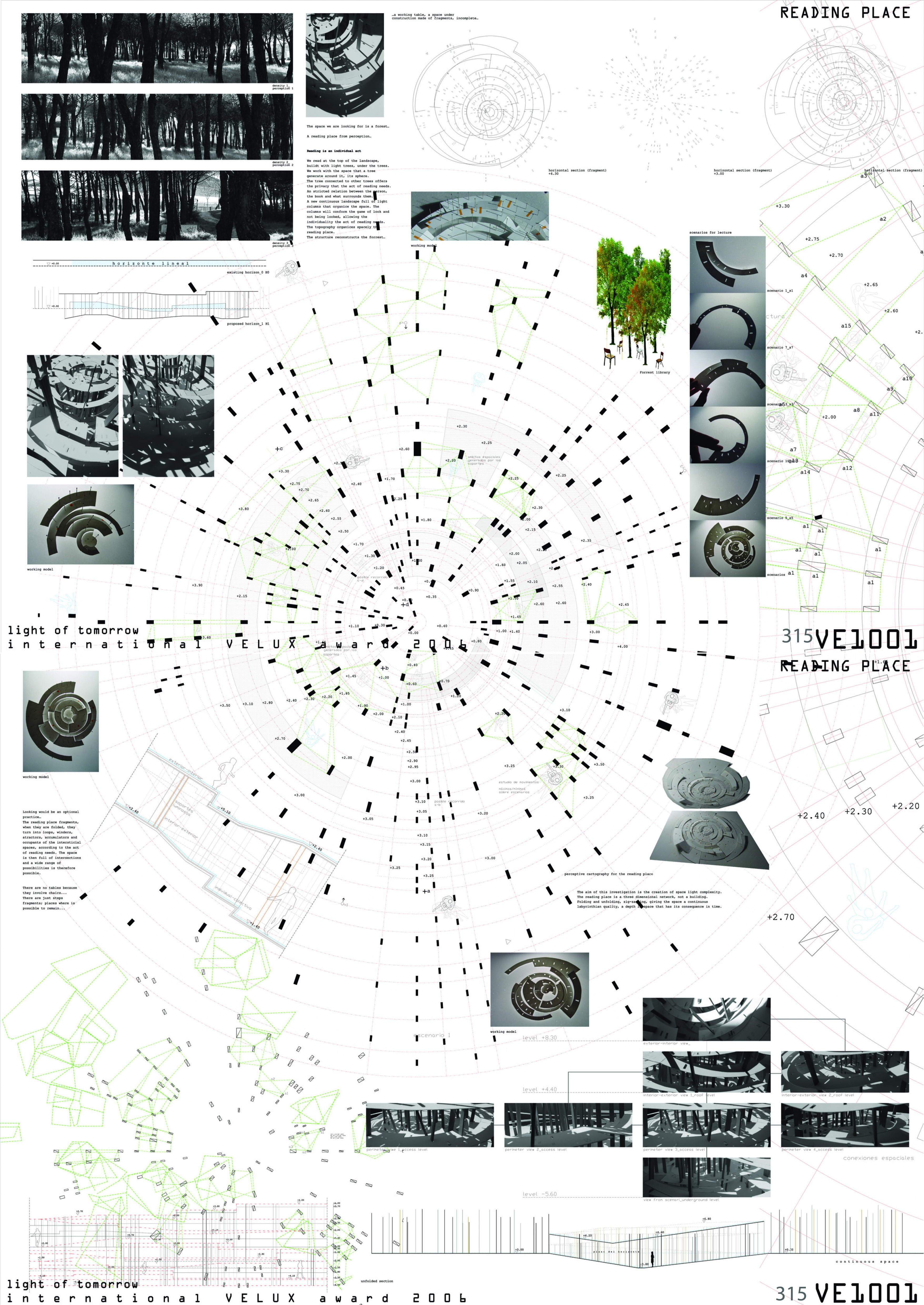

In order to improve the working environment for the workers in factories in the future while utilizing sunlight, we decided to insert light pillars and light sticks various from different sizes through the ceilings of the factories and into the added on indoor structure base on the floor plan. Since the ceilings height of these factories are usually around 9 meters to 12 meters, there are enough spaces to dangle huge sunlight pillars. These pillars function as medium between the inside and the outside of the factories and are made of solar control glasses that can reflect heat as well as UV rays to remain optimal temperature inside the factory. The top of these light pillar structures is consisted of tiny pieces of glass that are angled differently so that the light sources could reflect and accumulate with in the pillar itself, then sending the sunlight towards the workers.

Structural wise, the added-on structure inside the factory is with the purpose of supporting all the light pillars. It would be made of recycled electronic waste such as the hardware and motherboards, which can host every kind of digital technology, that can be quickly changed, dismantled, and when unused becomes part of the e-waste mass. These materials can be casted in transparent resin, arranged in tiles that can be moved and reused in the future. Moreover, we also took the cost of this project into consideration. The materials selected on top are both environment friendly and can be taken as one of the solutions to the electronic waste problem in the future. Design wise, instead of deconstructing part of the main structure of the factory, we decided to open the ceiling and direct the thick light pillars right through the ceilings, sending the sunlight towards the workers. This could help building a closer connection with the outside environment.

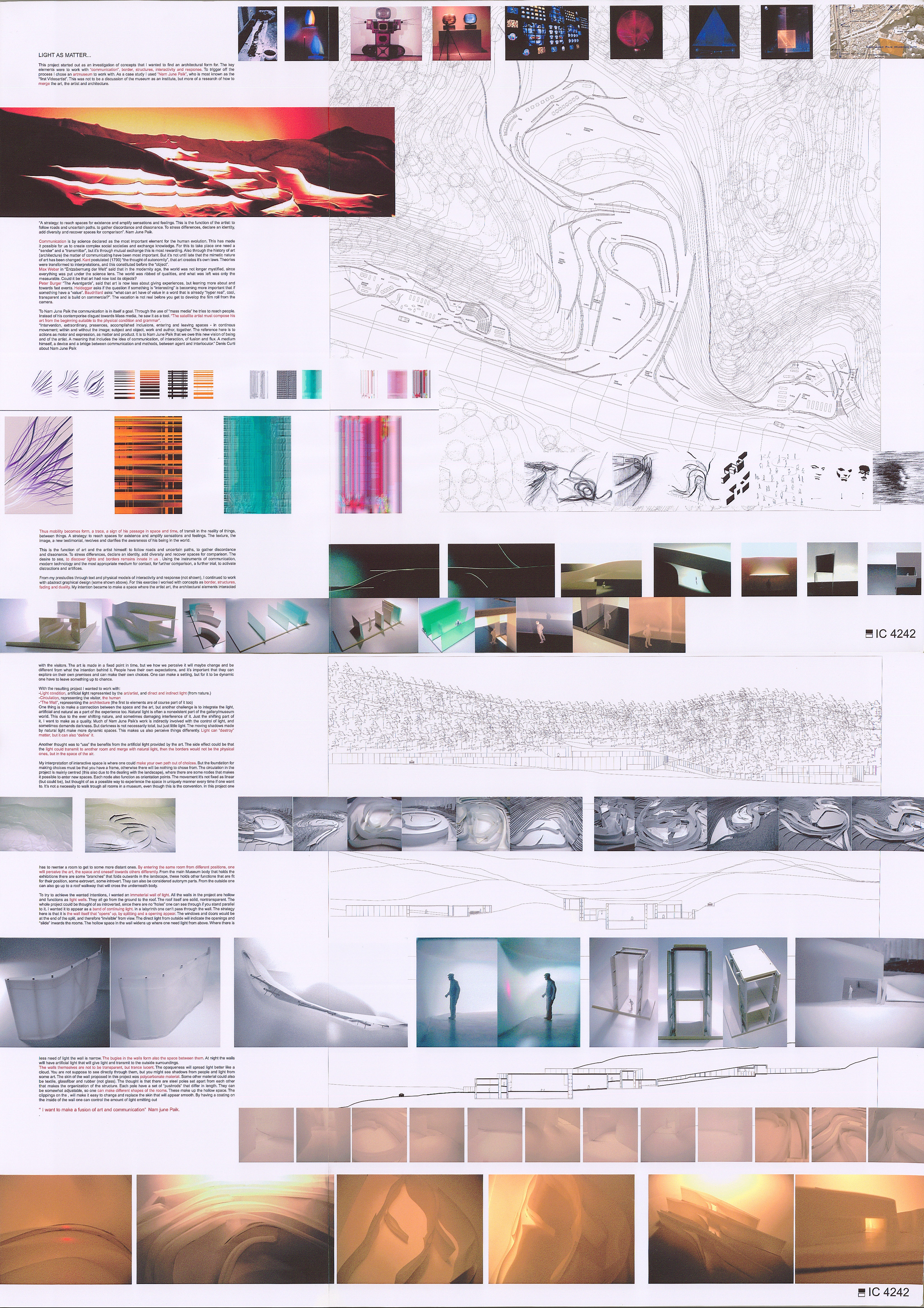

The concept of our project combines the elements of modern light therapy and the influence of light on biological timekeeping for the human body. The colors of these light pillars are interchangeable so that depends on the weather and the schedule of the factories, the colors of filtered sunlight could be adjusted. So that even on rainy days without much sunlight the colors of the light pillars are still able to have a therapeutic purpose. Each component of the light spectrum could be used for specific situations. On top of that, based on human’s instinct of moving towards light, dangling light pillars on top of each working area allows workers’ body to simulate as if they are in the outside environment even if they are working inside a windowless factory that is isolated from the natural environment.

While significant challenges remain, we feel like this approach of utilizing sunlight into electronic manufacturing factories could help improve the working condition for the employees while being environmentally friendly and sustainable in the future.