MaxLight

Category

Daylight in buildings - Region 1: Western Europe.

Students

ARMIN SHAMSEDDINI

SALAR AZIZIKALYANI

School

Politecnico di Torino

Country

Italy

Download

Download ↓

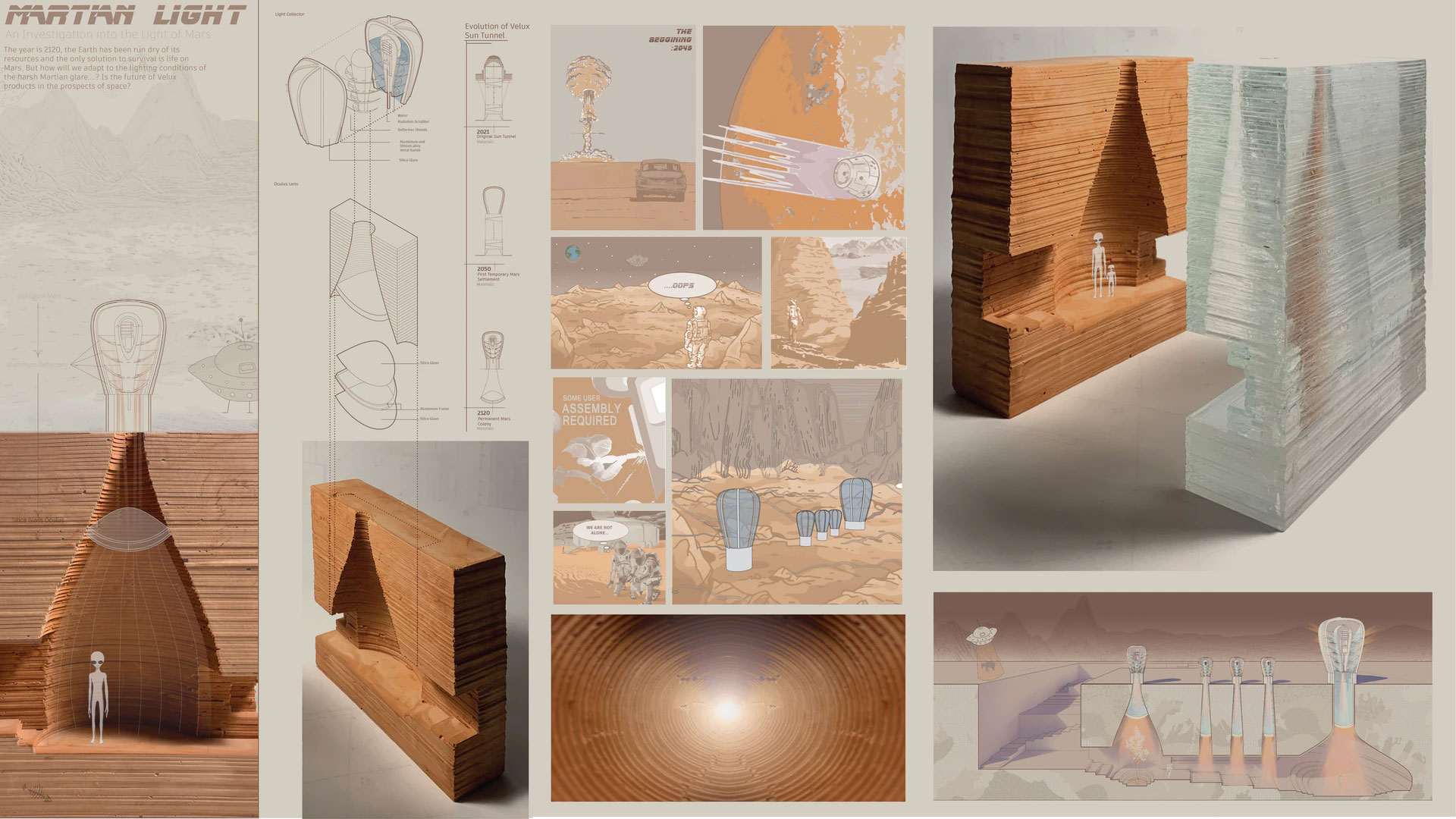

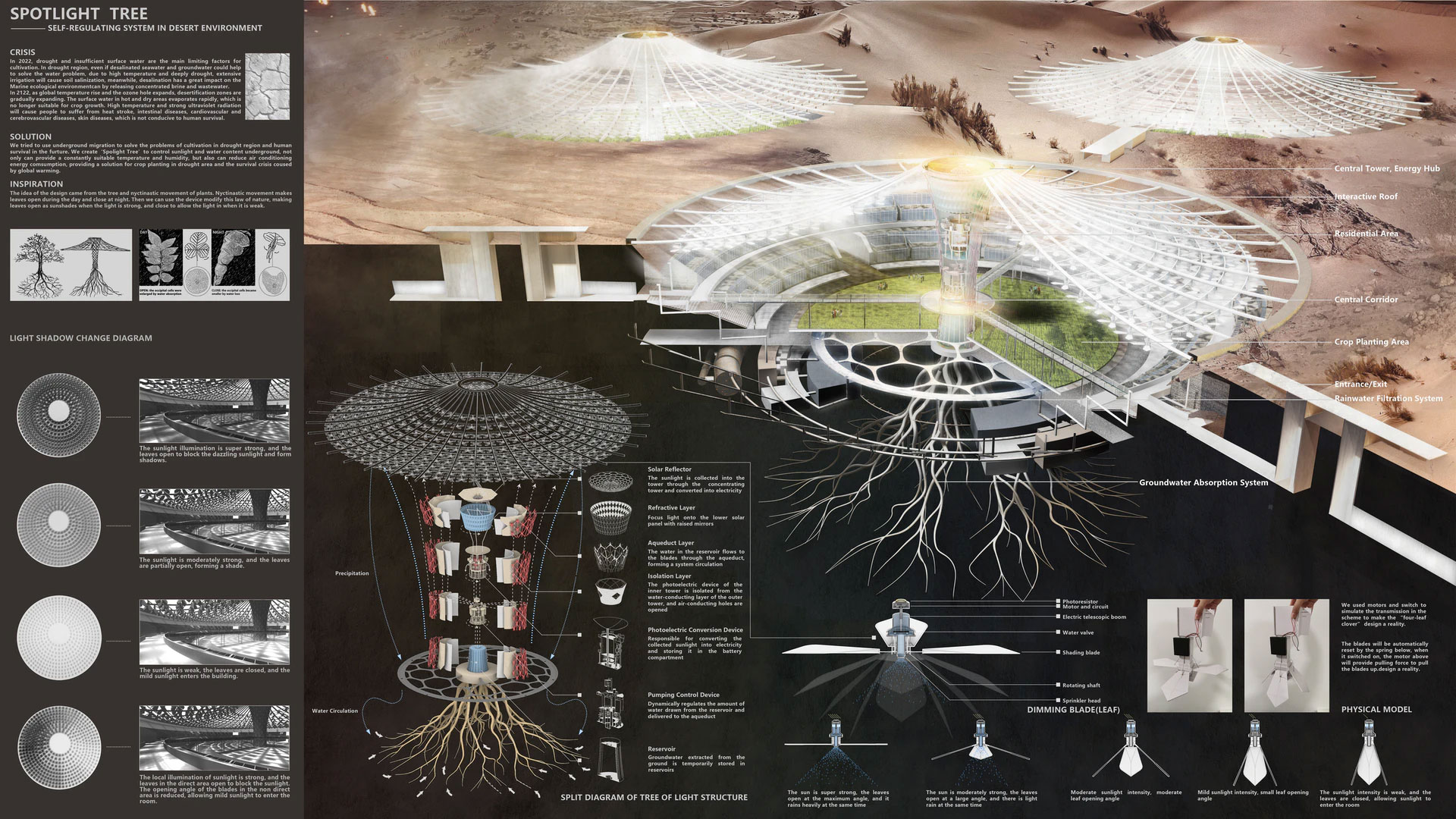

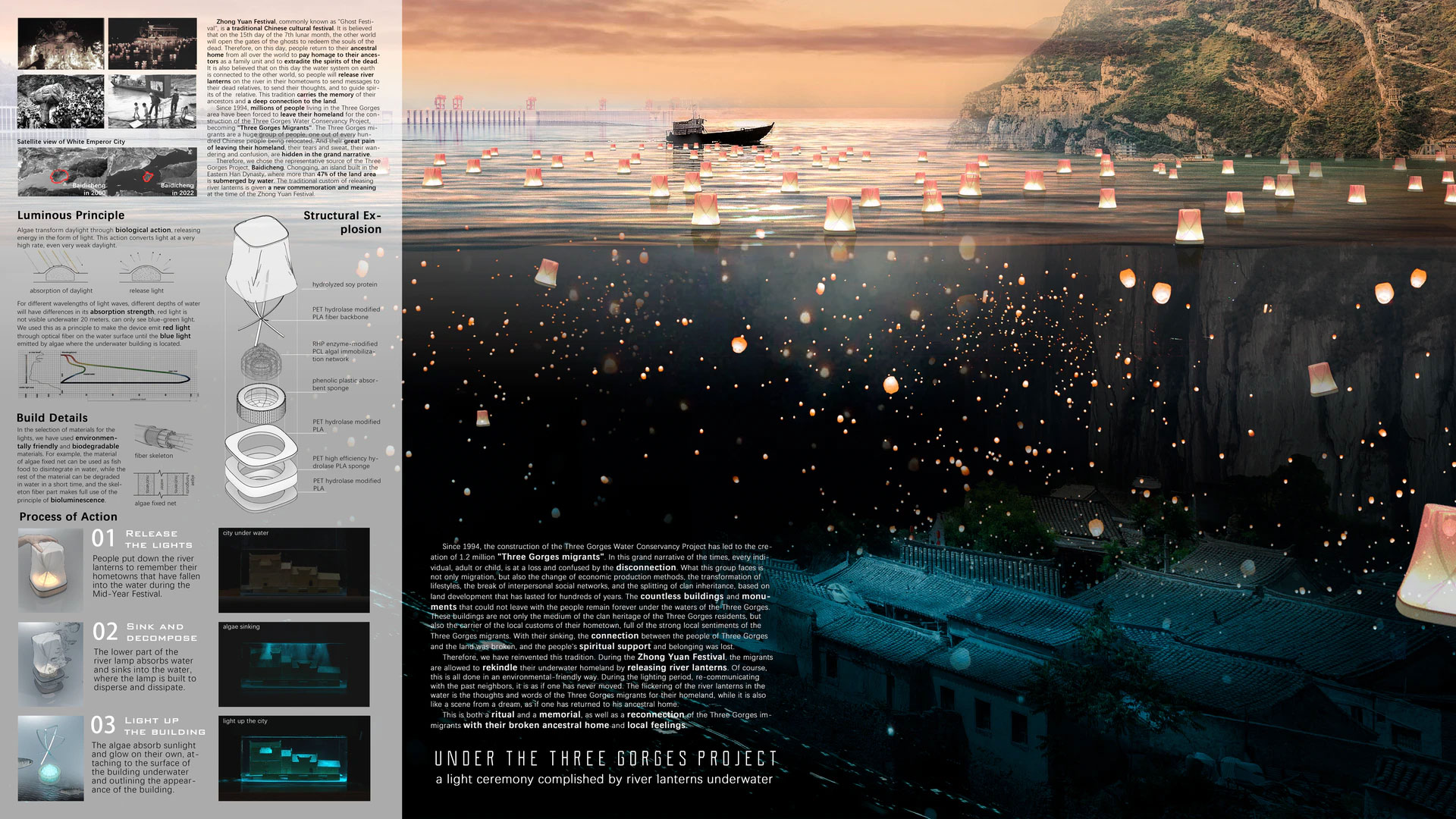

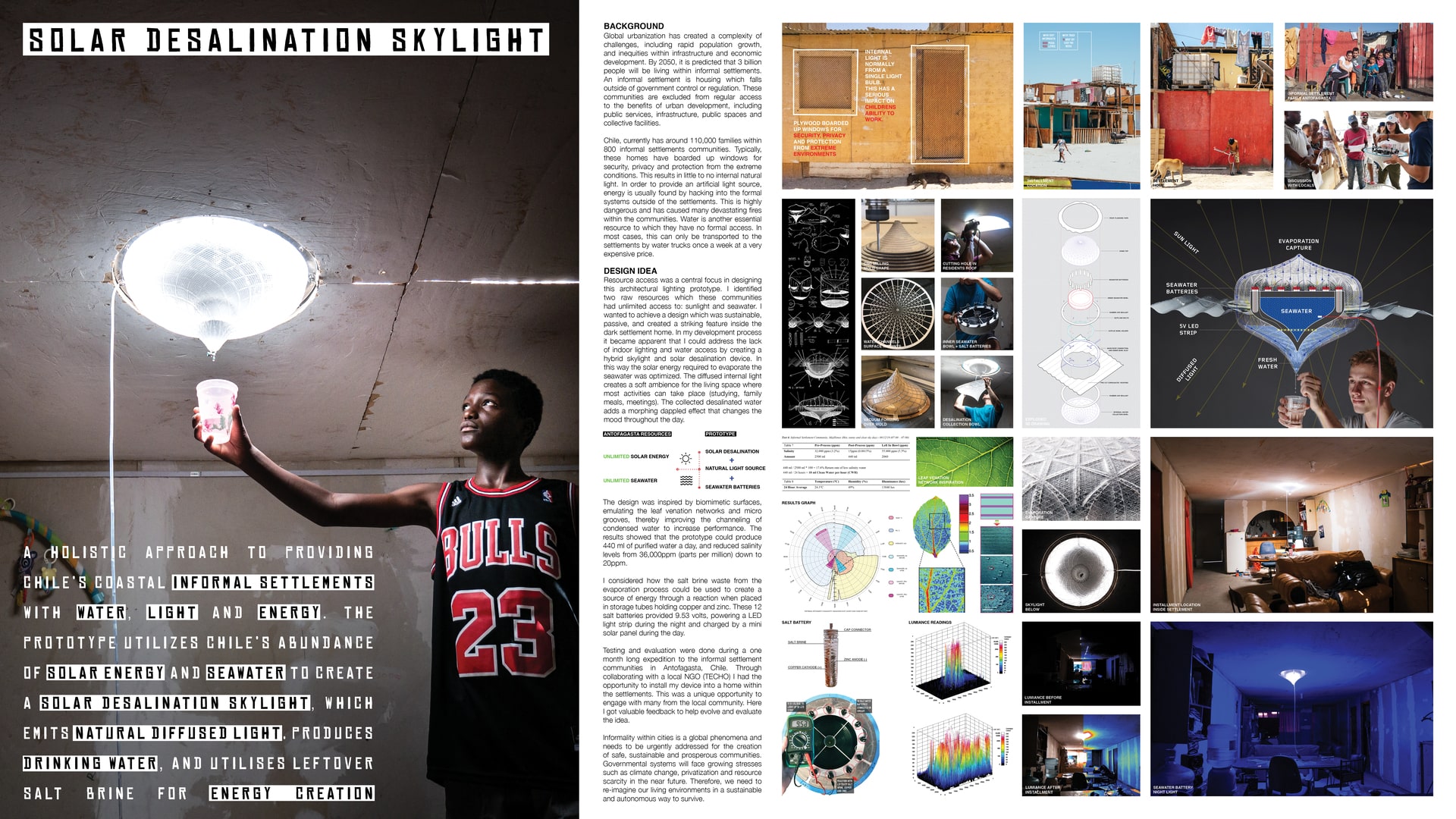

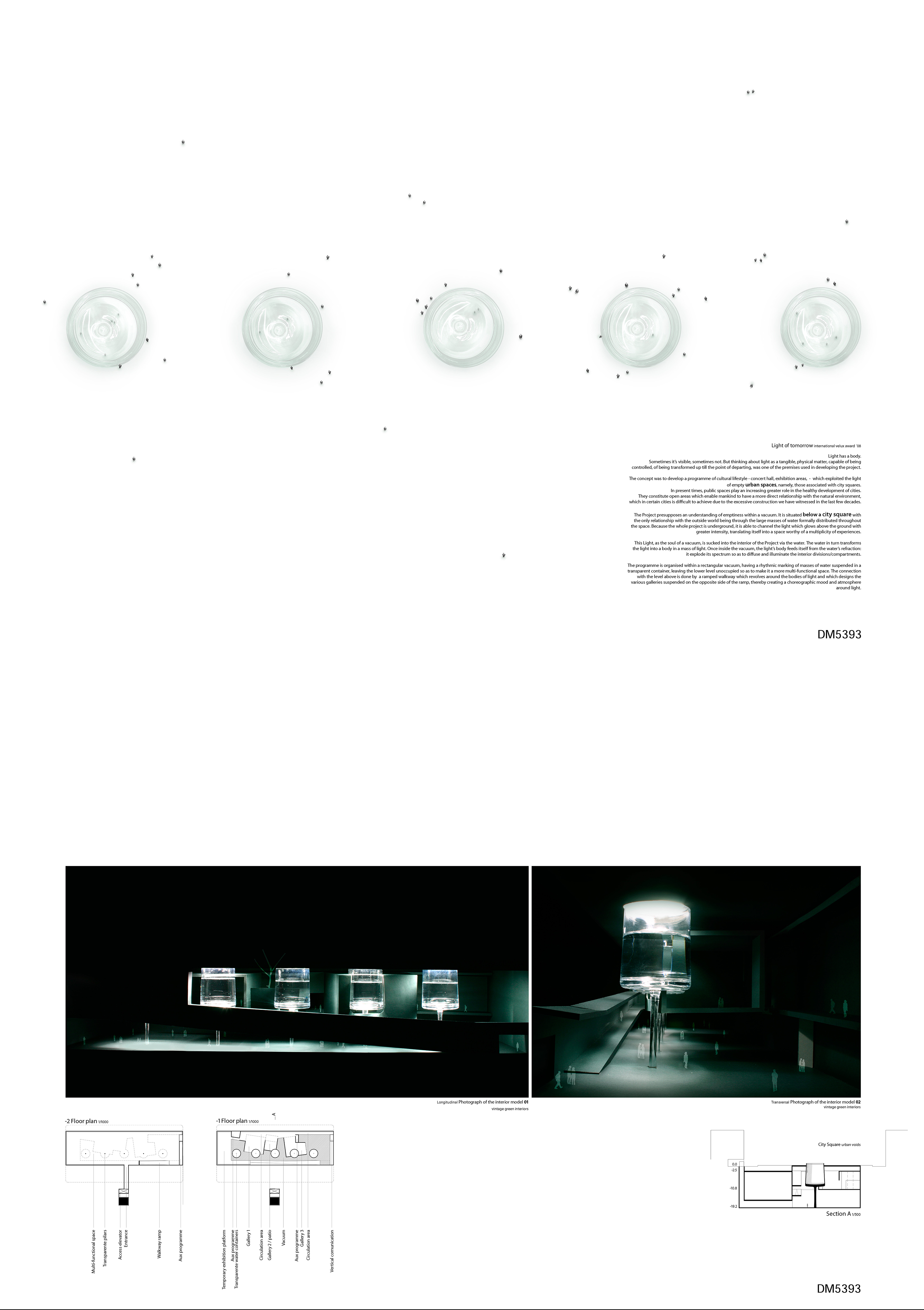

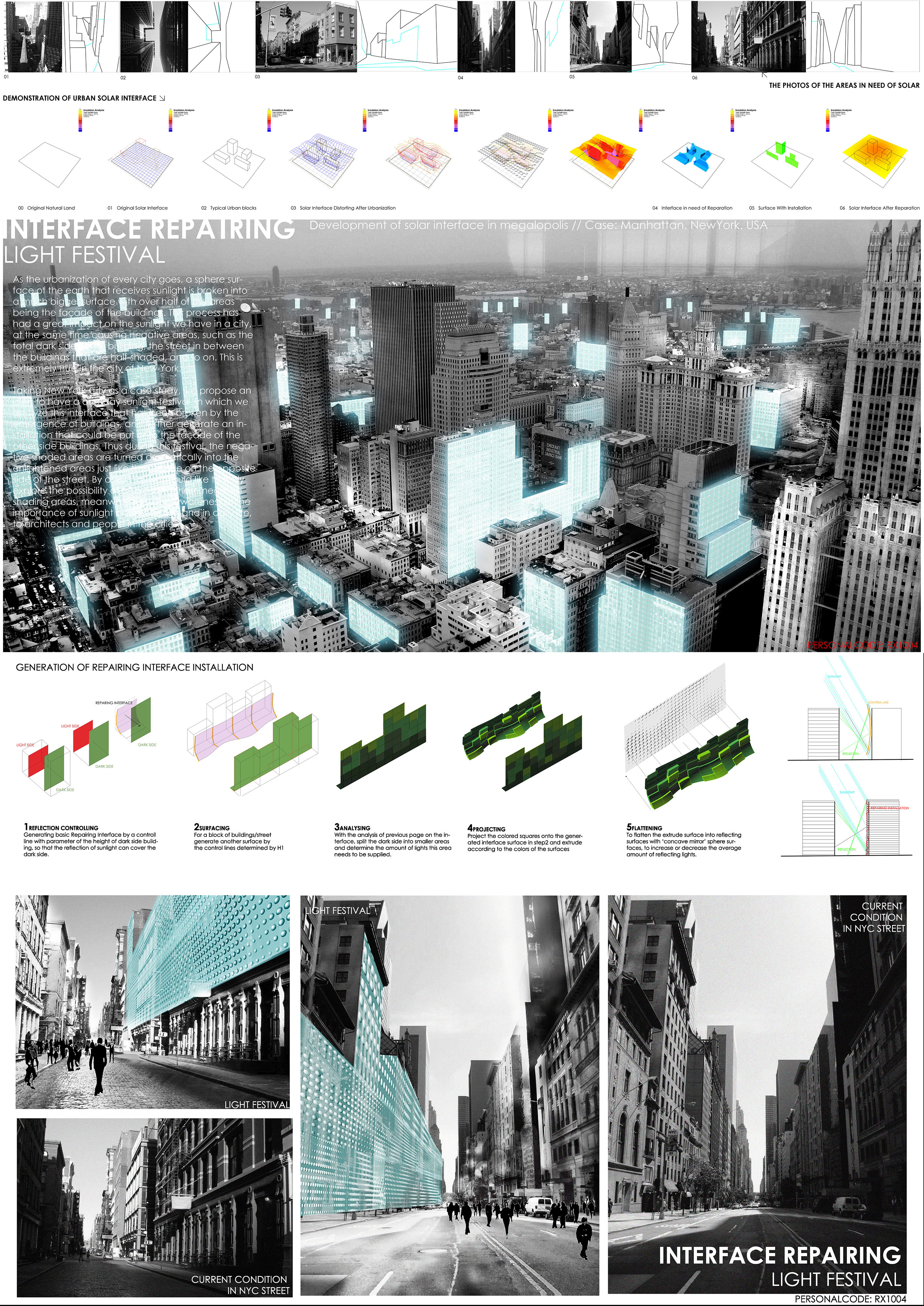

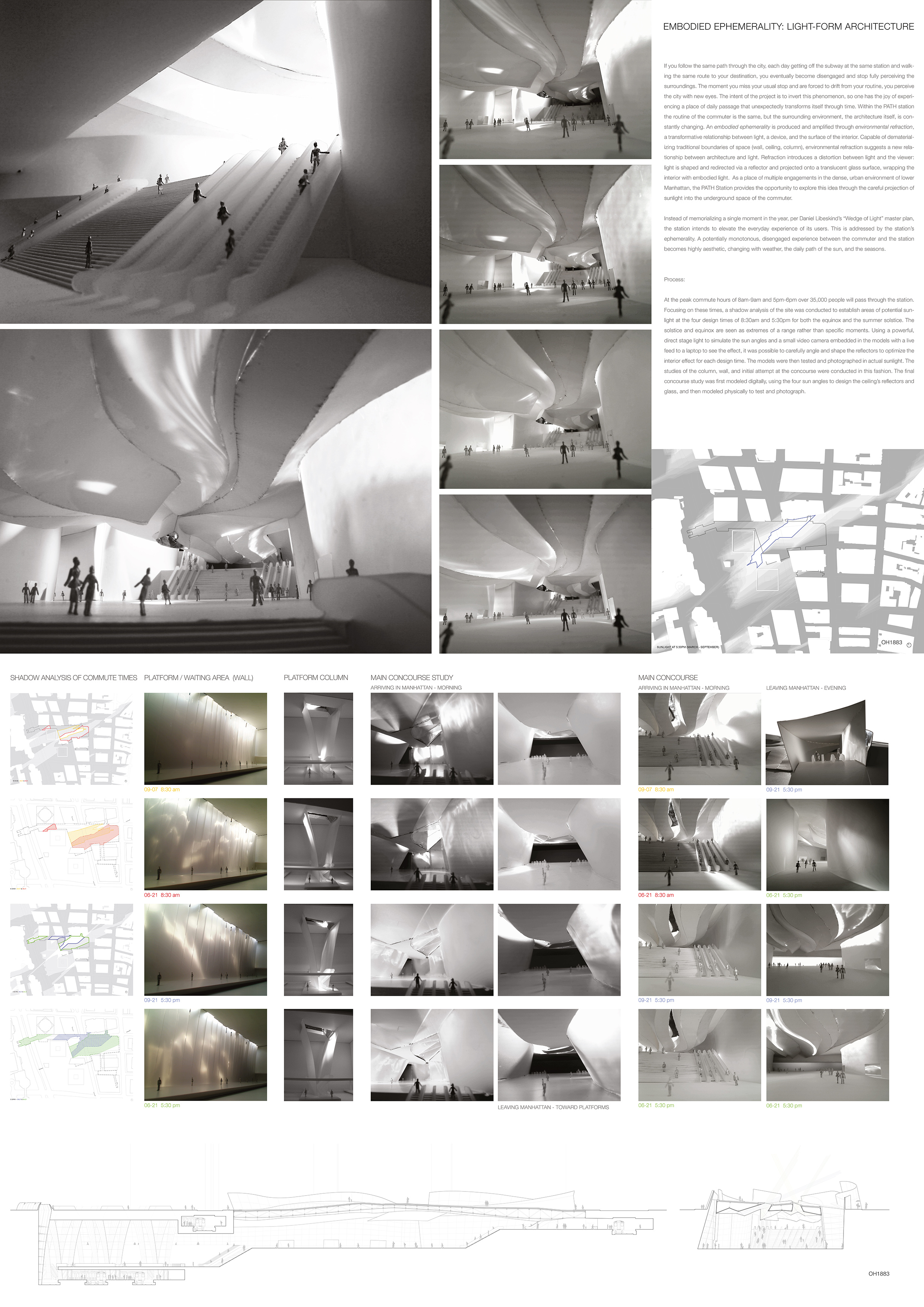

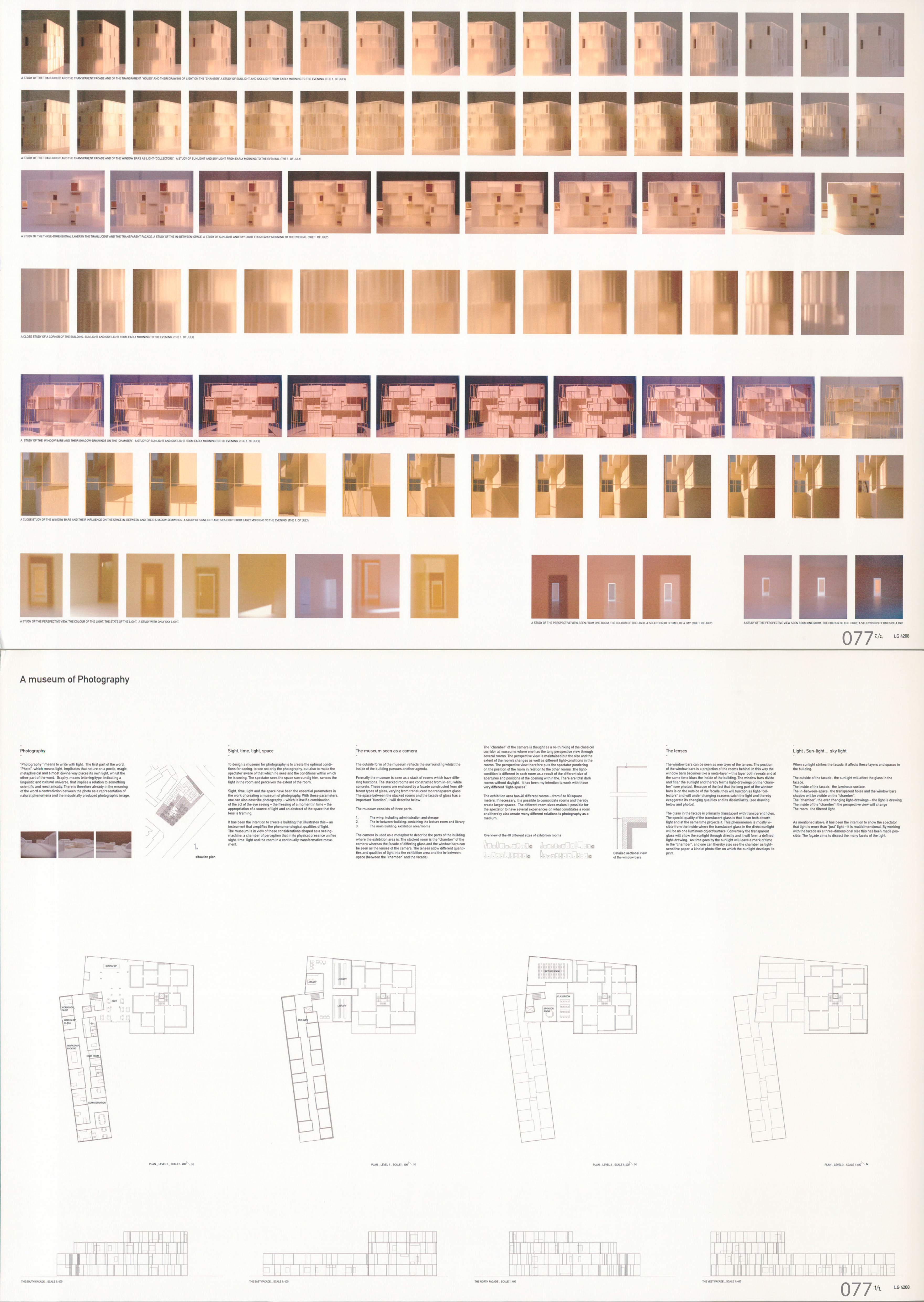

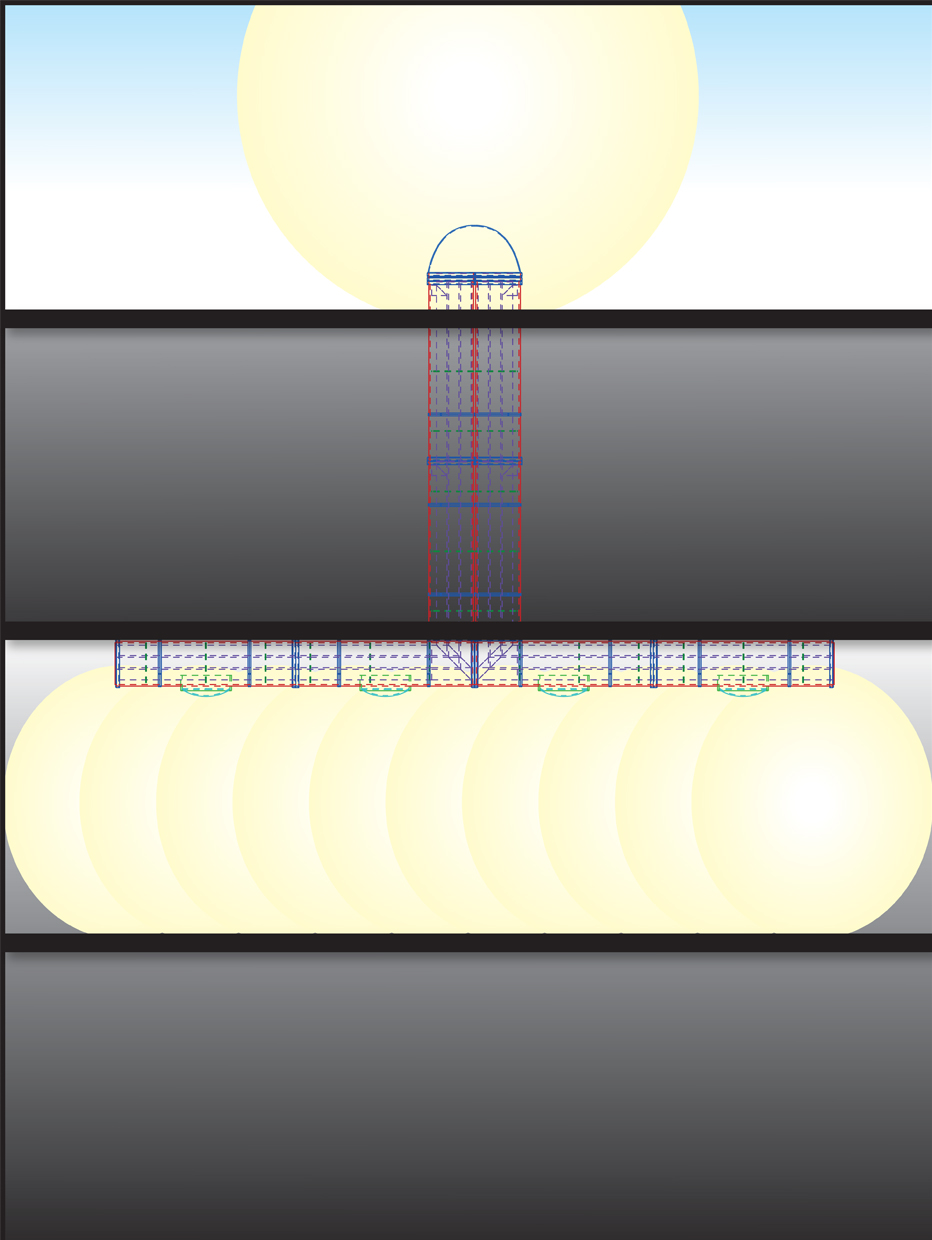

Project InformationSite location: Bologna, ItalyGrass floor Area: 657 m²Floors number: 3 + BasementIdeaNowadays, using sustainable and recycled materials getting increases every day. Plastic and light tube inspired us to create this product, also plastic is one of the most common, accessible and cheap materials in the world.ProblemThere is always some area in buildings that could not access daylight and need to use artificial light. Also, there are some products to direct daylight inside the building but they have limitations on height and length. On the other hand, their efficiency of them is less and during the transfer light power gets low.SolutionWhat is PMMA?Polymethyl methacrylate (PMMA) belongs to the family of synthetic polymers. It is a very transparent, hard material, with excellent resistance to ultraviolet rays and air. This material is capable of laser cutting, shaping, sanding, piercing, bending, etc.This material with the features that were discussed and will be discussed below, in the lighting and lighting industry has been able to become a suitable material for the implementation of some ideas. This material is the main part of optical fibers and is also used in the manufacture of special lights.PMMA is used in many cases because of its unique features. Almost the light conductivity feature is the most significant feature of this material. Conventional PMMA transmits up to 93% of light, which is more than other materials such as glass or plastic. This remarkable feature has led to its use in the manufacture of many lightings’ equipment.Hardness levels:• The surfaces of this material show good resistance against scratches and such damages. This feature will be very useful and suitable in cases where visual beauty is of special importance to us in the long run.UV resistance:• Because it is UV resistant, it is used for outdoor equipment. This material can be used in such spaces for a long time without changing the colour.Unique properties for unique performance:• In contrast, breaking this material is a suitable alternative to glass. It can also be improved by combining with other substances that enhance its properties. These changes in its composition are usually made to improve the properties of this polymer for special applications. Examples of features that can be adjusted in this way include impact resistance, chemical resistance, flame retardant, light scattering, UV filter, light effects, and so on.MAXLight ProductThis product is designed in three main parts, the first part which is the head of the product with a circular shape, install on the roof that collects light and sends it to the inside of the building. The second part is the tube of product that transfers light to dark places. The last part is a light valve to distribute light in the room.This product is designed semi-circular shape that inside includes several PMMA rods (light rods), they are supported with some plans. This semi-circular is covered by transparent plastic.There are some advantages to using this product in building like use on more than two floors without losing efficiency of light. Also, it is a flexible material that can turn in several angles to fit with all the plans of buildings and use as a part of interior design because of shape and product design this material using inside the building. On the other hand, the price of this material is too cheap, which can be economic for customers.Case Study The big area of the second floor was selected to use by our team as an example to show how is working MaxLight system. The effect of PMMA product on the building’s inside to use more daylight. You can see a difference in light factor in the below section with the second floor with other floors.