Even a mudbrick

Category

Daylight in buildings - Region 1: Western Europe.

Students

Bogdan Stoicescu

Mathieu Jollet

Jad Nehme

Teacher

Jean-Luc Capron

School

Université catholique de Louvain

Country

Belgium

Download

Download ↓

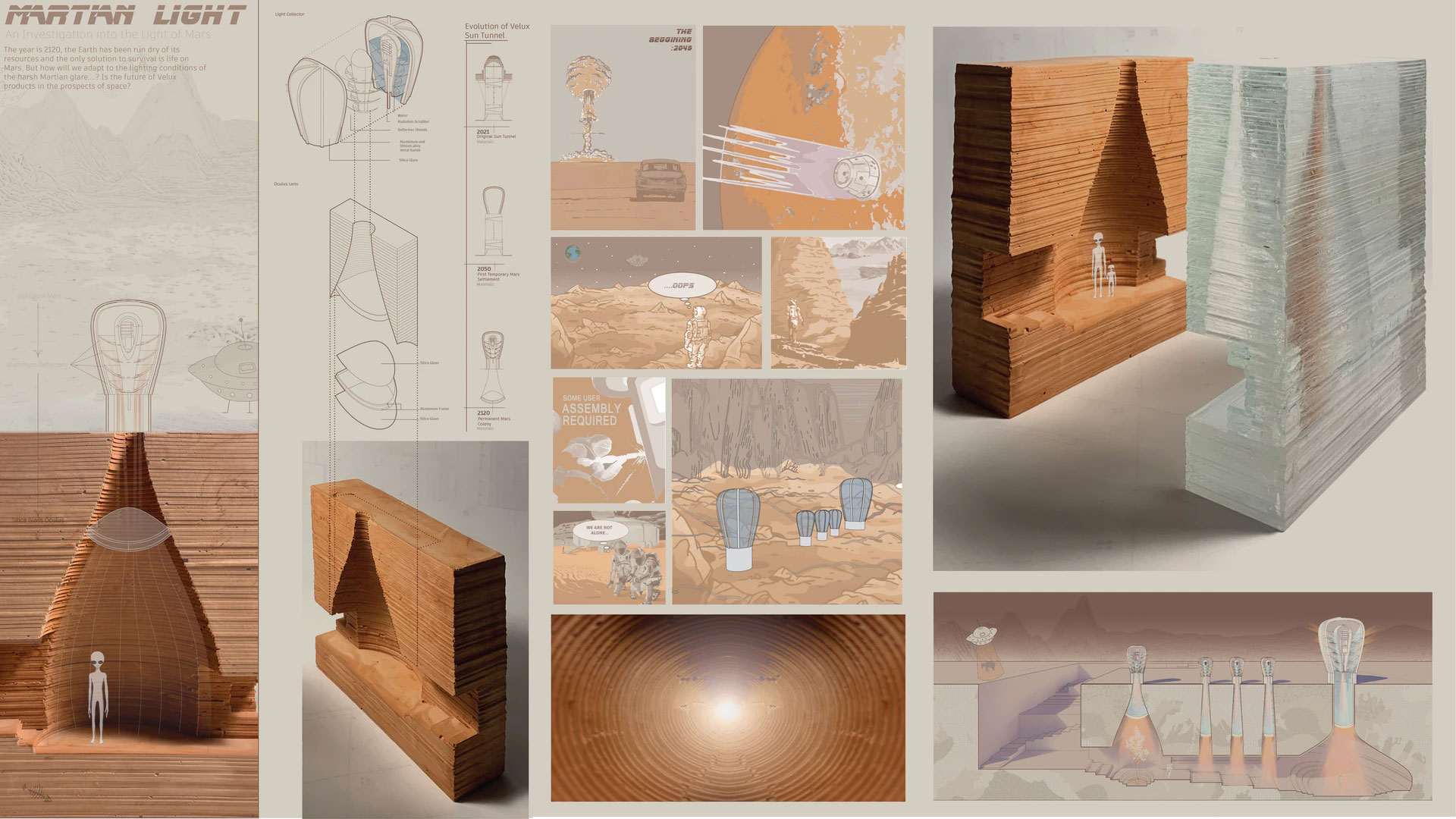

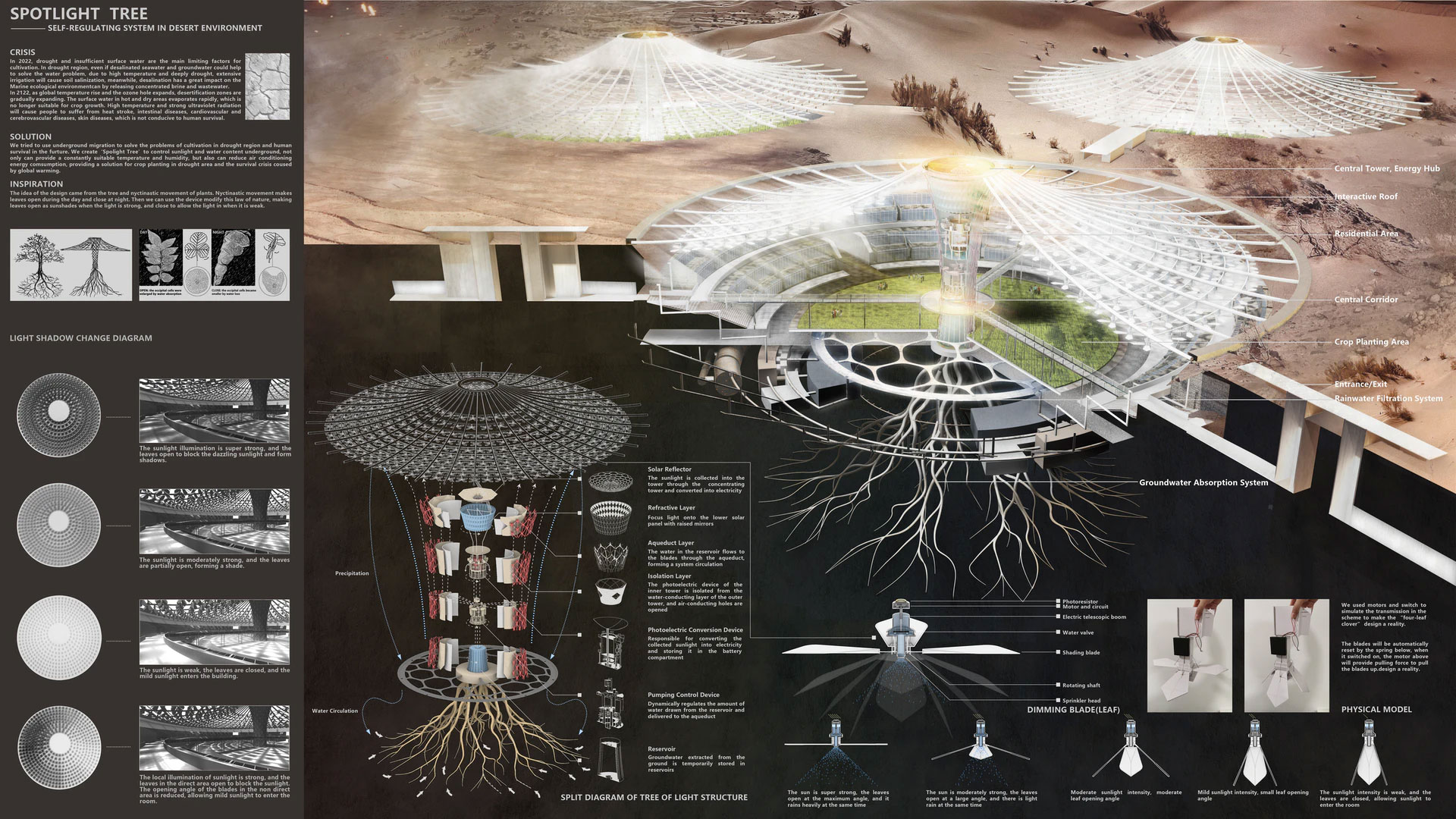

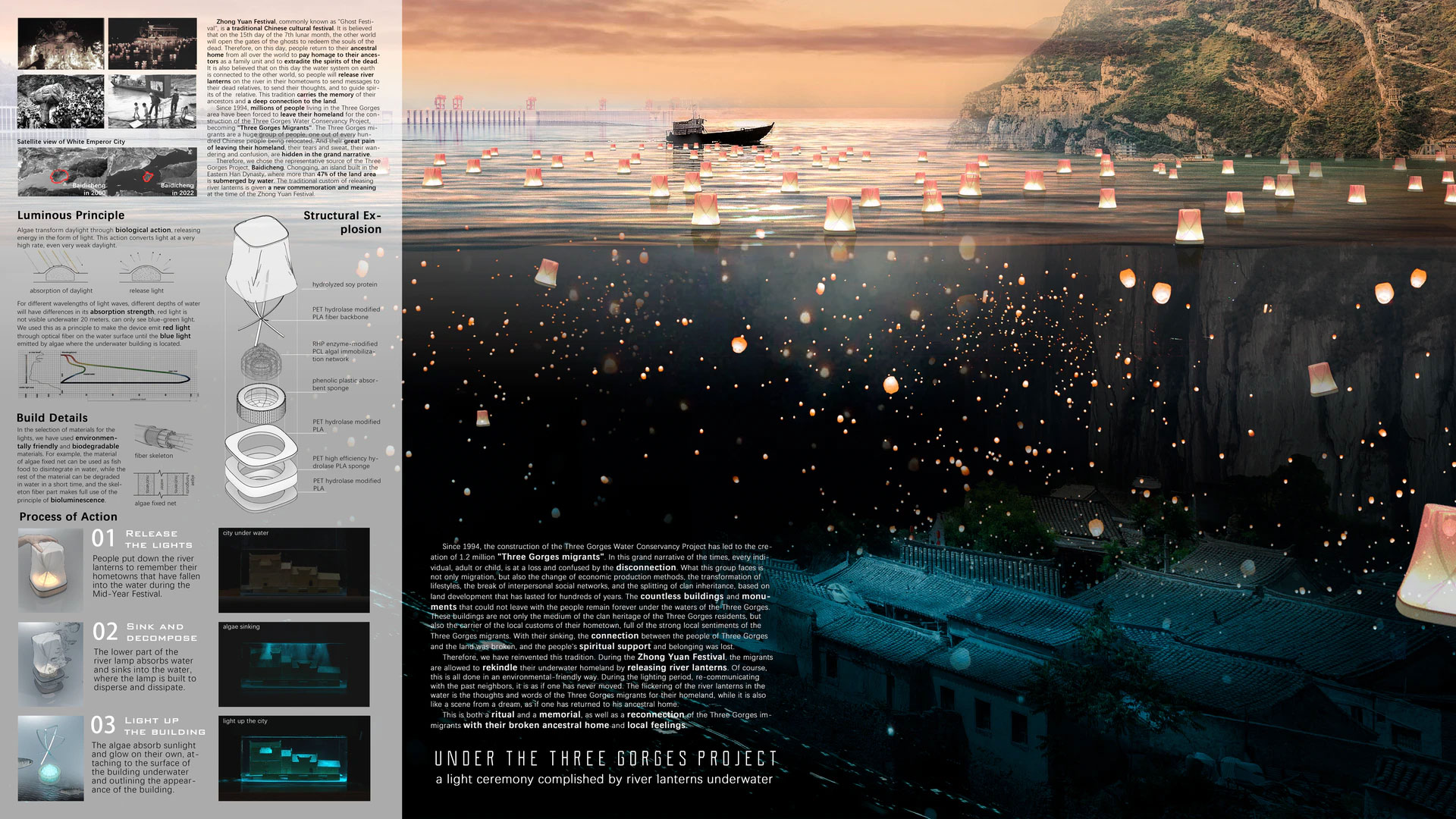

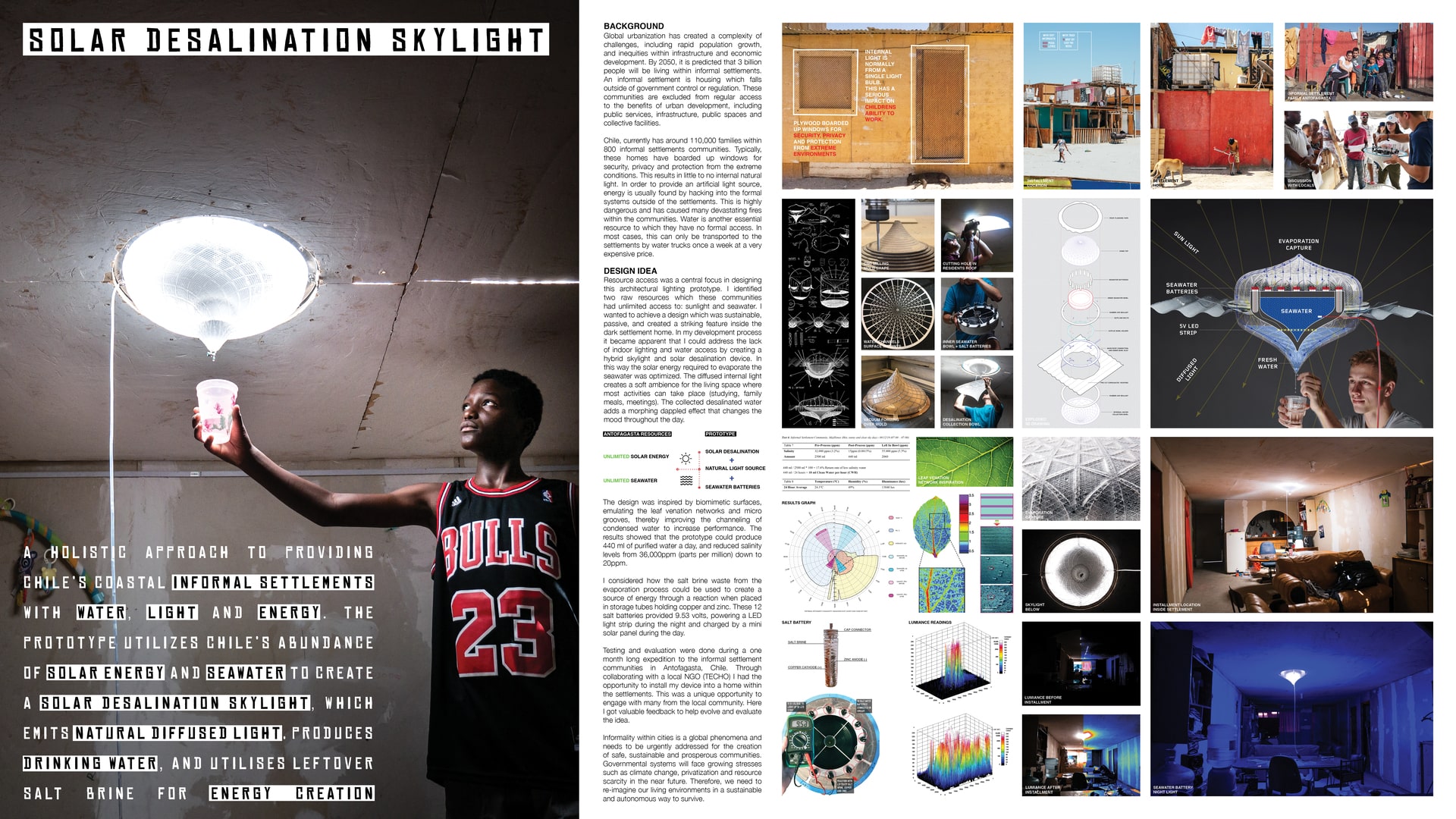

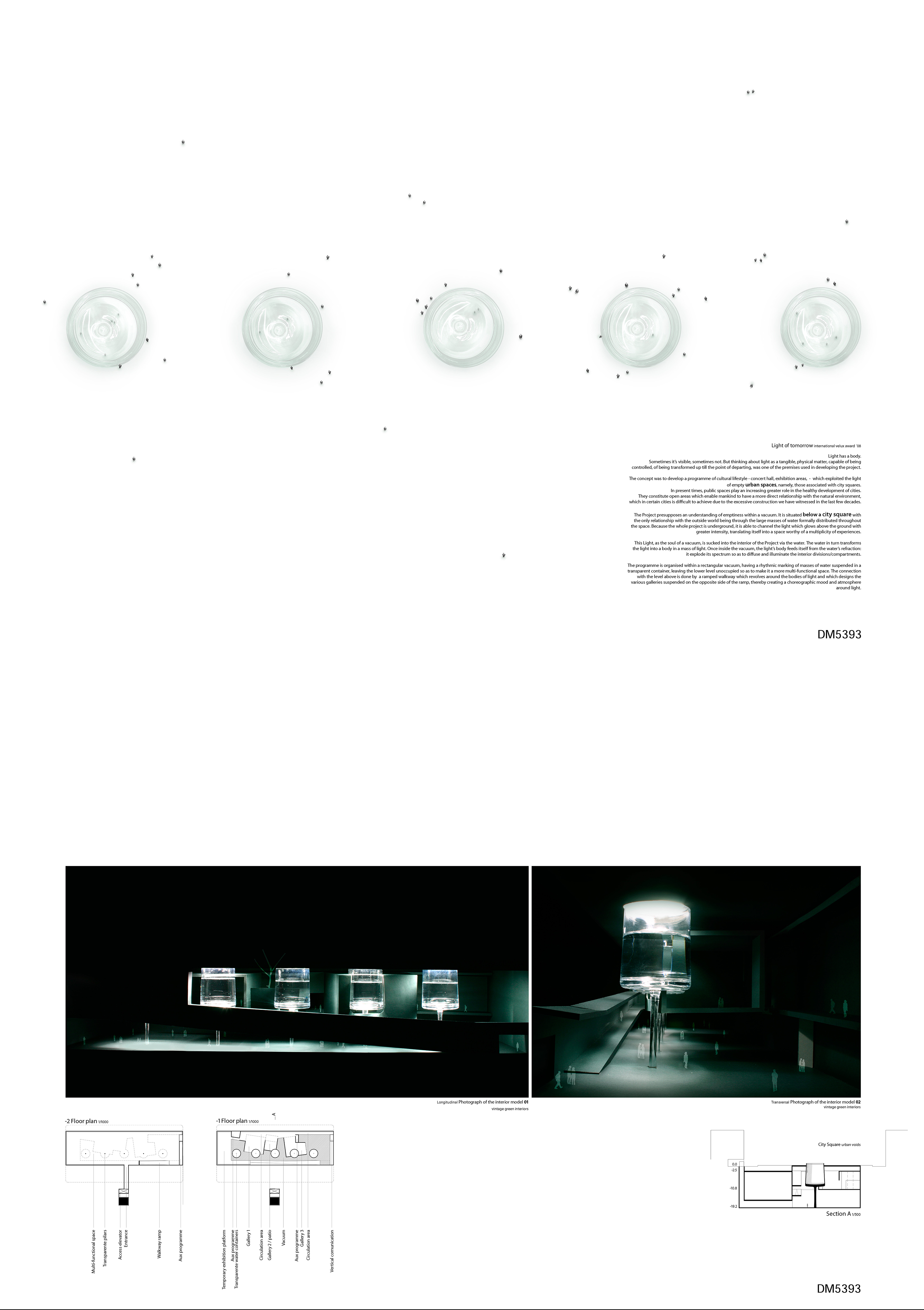

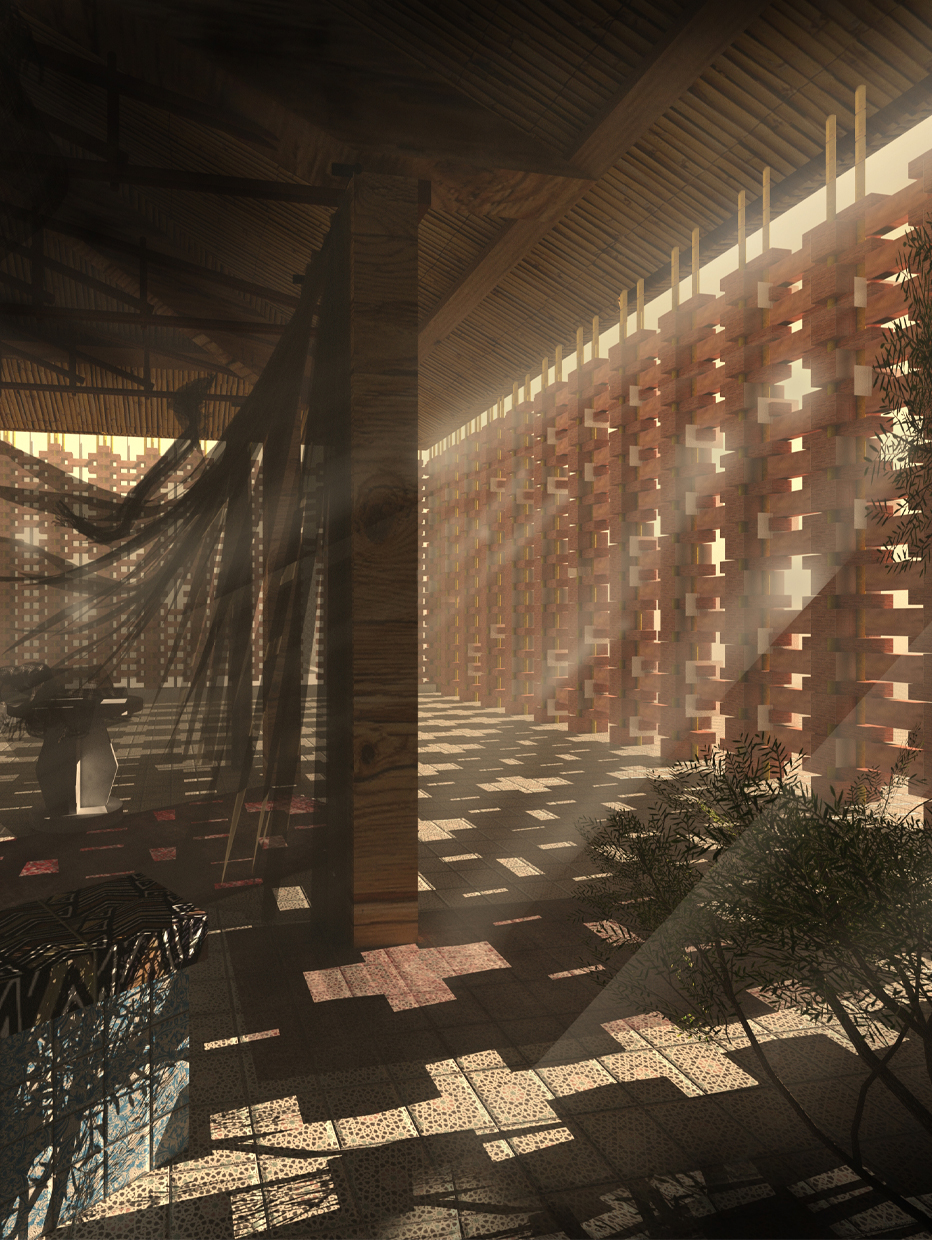

We view architecture as “sustainable poetry”, capable of addressing both old and contemporary societal challenges. Brick making industry provides employment to millions of people worldwide. In the non-mechanized brick kiln industries of the developing countries, the labor-intensive manual work of molding clay into bricks employs a vast workforce, the majority of which unskilled, working in harsh, unsafe and unhealthy conditions, often causing them respiratory diseases. The global industry of fired bricks presents not only an obvious ecological impact on the environment, as brick kilns burn 375 million tons of fossil fuels like coal and biofuels like timber each year, but also an important social one.With a “Think global, act local” approach in mind, we seek to bring light “to the rescue”, to ease the strain of brick kiln industry on the environment, by proposing three different types of non-structural modular pierced walls made either entirely out of mudbricks or in combination with reused fired bricks. These walls offer not only basic comfort needs like lighting and ventilation, but can also create temporary shelters to brick workers near kiln sites or in hospital buildings.Combining earth, water, sun and air, straw-reinforced mudbricks are naturally “baked” in the sun without an oven or kiln, proving more ecologically-friendly. When the building is discarded in the future the mudbricks will go back into the soil. Therefore, we envision three types of walls, as follows:The first two wall types combine reusable fired bricks from the kiln sites nearby and newly made mudbricks. We propose a symbiosis between fired and unfired bricks in the same structure, combining the strength and durability of fired bricks with the thermal capacity, greater mouldability and aesthetic qualities (more variety in shape, color and texture) of mudbricks. The ratio between fired bricks and mudbricks for the walls are 2:1 and 3:1 respectively, therefore reducing the amount of fired brick needed to build the walls. The walls are comprised of independent vertical modules of fired bricks that are stacked one on top of the other, reaching variable heights, in an alternating 90-degree cross pattern, without the use of any wet binder, in order to reduce the use of mortar or cement, and to assure their later reusability, being hold together only by long bamboo sticks, which pass through the holes of bricks, like an “armature” that makes use of bamboo’s greater-than-steel tensile strength. The resulting interstitial spaces between these vertical modules are gradually filled up with freshly new mudbricks, that have already passed a first phase of drying (3-4 days up to a week). During the second and third phase of sun drying, the mudbricks are already strong enough to be inserted in between the fired bricks that act like a support “shelf” for them, laying for another week on their long narrow side exposing their broad face on the first wall, then vice-versa in the second wall for another week. Mica sheets or reused tin cans covers can be placed between the fired bricks and the bamboo sticks to further reflect light upon the mudbricks, creating an interesting “infinite mirror” (mise-en-abyme) effect.Due to the modular nature of the first two walls, the distance between the vertical cross columns of fired bricks can vary, to accommodate different sizes of mudbricks. These first two walls can then easily be attached to vertical elements like a wooden roof or a concrete slab floor using the strong bamboo sticks lower and upper ending as structural joints, thus resulting in a very basic yet poetic shelter for brick kiln workers, which lets the sun “work” while they rest! After having dried in the sun with the help of the two wall types, the mudbricks are finally laid in the third wall type, which is also composed of alternating vertical modules in a cross pattern with the mudbricks standing up on their narrow side, to reach the desired height with fewer bricks, while the in-between module is made up of mudbricks facing one another at 45-degree, in order to create the Venturi effect which provides enhanced natural ventilation, reduces the energy input required by other means of artificial mechanical ventilation, allowing cool air to pass through, and making the interior more pleasant during the high temperatures in summer. As this wall type is made entirely of unfired bricks, the enhanced air flow will be much healthier, therefore we envision the type of wall to be used in local hospitals where kiln workers with respiratory conditions can be treated.Intricate play of light and shadows, aesthetics and functionality, turn simple mudbricks into humanitarian architecture, that strengthens in time and in daylight! As Louis Kahn once said, “Even a brick wants to be something”.